From standard caps to custom made

Kornelis Caps & Closures, based in Steenwijk, produces plastic caps and closures for both food and non-food products. The company offers standard sizes as well as fully customized designs and specializes in sealing jars and bottles. Kornelis also invests in technologies such as IML decoration and engraving to give packaging a stronger visual impact.

During the interview, the meeting table is covered with caps in all kinds of colors and designs — a clear showcase of what the company can create. Corry Dijkstra, Sales & Marketing Team Leader, and Marco Lankau, Internal Sales Representative, explain the wide range of their product portfolio.

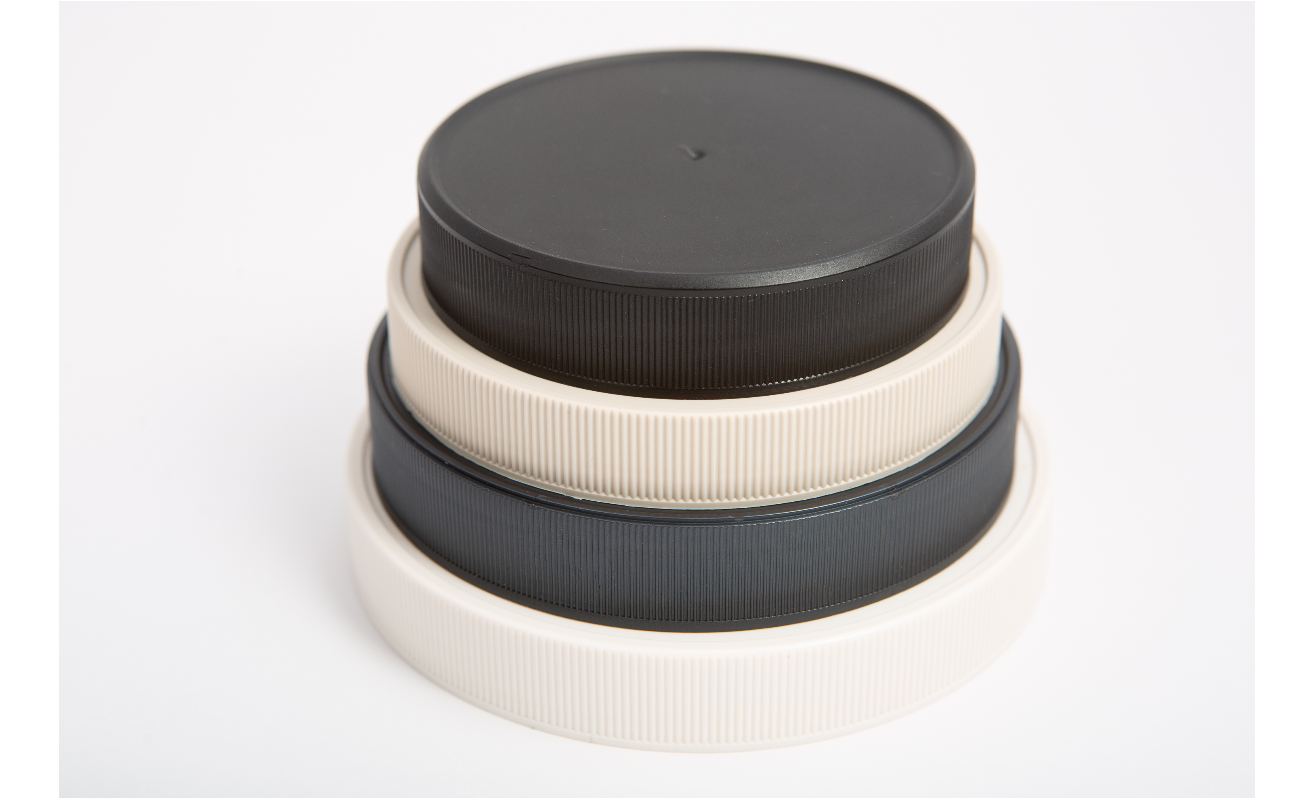

“Our caps and closures range from 38 to 120 mm,” Lankau says. “We offer popular wide-mouth sizes — including 66, 82, 100, 110, and 120 mm — as well as sprinkle caps in 38, 63, 82, and 85 mm, and various sauce caps. Each product can be customized — color, height, finish, type of liner, and application all define the final configuration.”

From Standard to Custom Solutions

Kornelis offers a wide range of caps and closures, from standardized models to fully customized solutions tailored to specific customer needs. Lankau highlights a recent case for oils and vinegars: “What you see here — these black caps — is a more efficient design with fewer components and lower weight. It’s a great example of how we not only respond to our customers’ needs but also actively help reduce material usage.”

A customized cap variant requires an investment but delivers a unique solution that perfectly aligns with the customer’s brand identity and functional requirements. Dijkstra adds, “Tooling sets or insert parts require lead time. Completely new, customer-specific molds take more time and cost more, but they provide years of continuity for the customer.”

"Custom-made molds provide years of continuity for the customer”

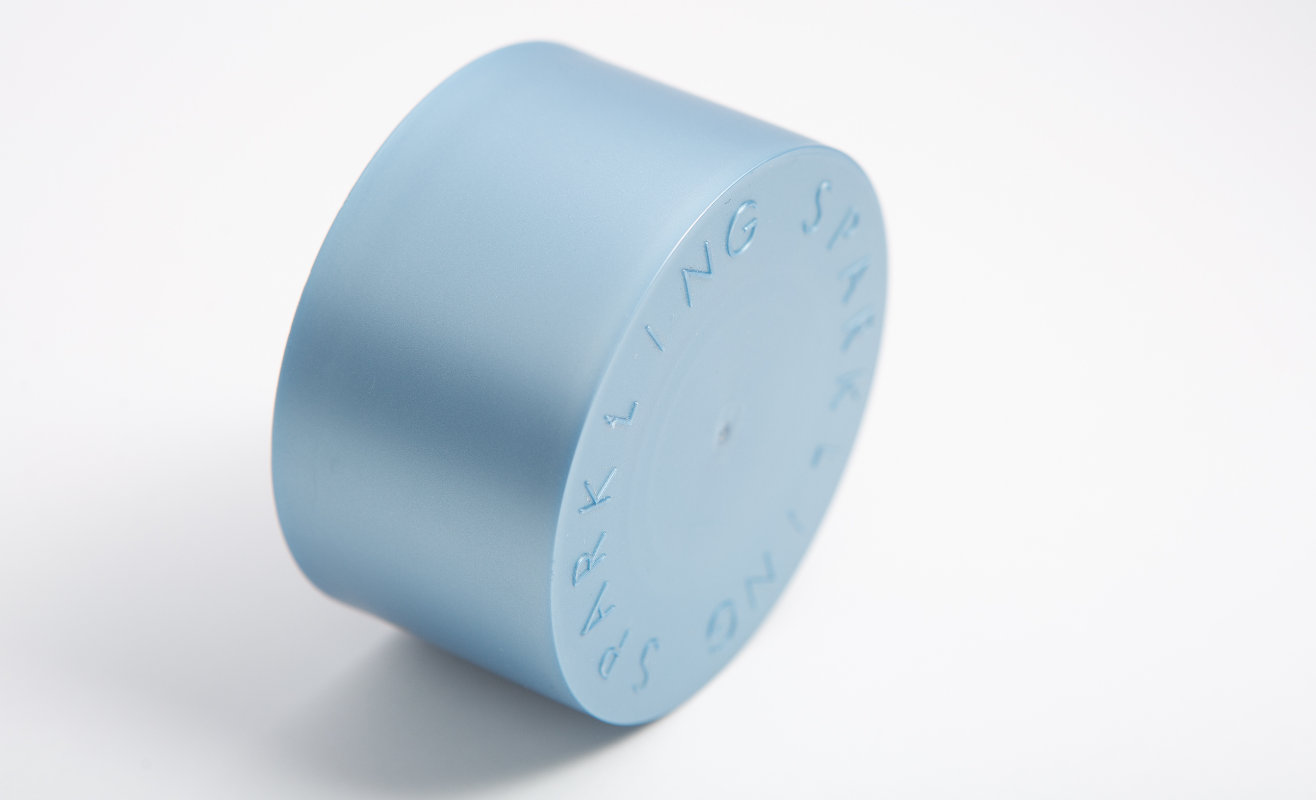

IML and engraving

In-mould labelling offers customers a cost-effective and sustainable packaging solution and makes the brand look better with high-quality visuals. Kornelis offers single- and double-sided IMLs, which work best for large orders. Lankau says, “With IMLs, you can skip a labeling step; the customer gets a ready-to-use cap. The cap is made from one material, so the cap and the label can be recycled together.”

Kornelis also offers engravings for a more luxurious look, often with a matte or textured finish. Dijkstra says, “IMLs and engravings help people recognize the brand. Which one you choose depends on how you want it to look, the size of the order, and the market.”

Recycled materials and bioplastics

For the non-food sector, Kornelis actively uses recycled materials (regenerates). Dijkstra says, “Because recycled material behaves differently than virgin plastic, we worked with suppliers to achieve stable colors and performance.” Availability and price remain important issues. “Recycled plastic is limited in supply and more expensive than virgin plastic. Customers need to be willing to pay the higher price.”

For food applications, recycled materials are not yet allowed due to food safety rules. Dijkstra adds, “Biobased options are technically possible, but the market is sensitive to price.” Kornelis follows FSSC standards and is ISCC PLUS certified for mass-balance and biobased streams.

"For each packaging model, we analyze where material savings are possible without losing functional properties.”

Tamper evidence and liners

A key strength of Kornelis is combining caps and liners (seals). The company can supply caps and closures with a wide variety of liners based on customer needs. Options include induction foils, adhesive foils (with or without backing), and pressure-sensitive liners. The choice depends on the product (fat content, viscosity), the container (glass or PET), and the packaging line. Dijkstra emphasizes practical testing: “We advise and test with samples and endurance trials. Only when the product works well on the production line and food safety is guaranteed do we approve it for production.”

Kornelis also actively supports aftersales with line issues. Dijkstra says, “If something goes wrong, our colleague Willem Koppel from customer service visits the customer. By working together to examine the machine and analyze settings, a solution is often found. That problem-solving adds real value.”

Trends in design and market

Kornelis sees growing demand for matte finishes, wood textures, and a ‘luxury look’ with engraving, especially in the bio and cosmetics segments. The sports nutrition market is growing fast and remains a heavy user of wide-mouth caps. At the same time, efforts are being made to reduce weight. Lankau says, “For each packaging model, we analyze where material savings are possible so the weight can go down without losing functional properties.”

There is also increasing demand for carbon-black-free black caps because they are easier to sort visually in the plastic recycling stream. Lankau adds, “NIR-detectable colorants help in waste separation. This improves recyclability and the chance the cap ends up in the right stream.”

Dijkstra explains how regulations and the market connect: “The Packaging & Packaging Waste Regulation forces customers to make choices: single-material streams where possible, less weight, and fewer parts. We have the knowledge and expertise to advise on this and offer a PPWR-compliant closure. Kornelis is happy to help.”

Would you like more information about our caps and closures?

Get in touch with us. Our specialists are happy to help you further.