Towards a digital and sustainable future with new injection moulding machines

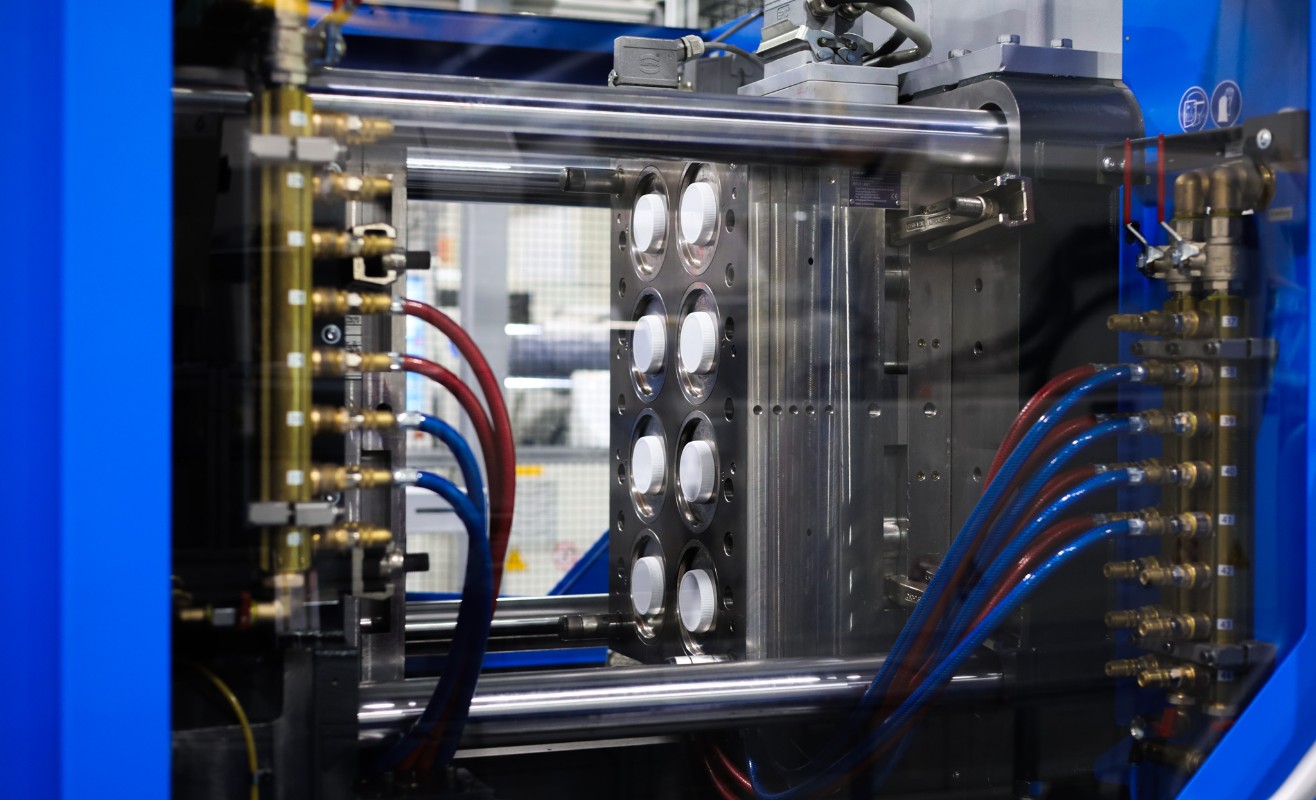

At its production site in Steenwijk, Kornelis Caps & Closures operates 24/7. The recent acquisition of three new fully electric injection moulding machines from Sumitomo-Demag – the IntElect2 Speed version – marks a new milestone in the development of caps and closures for the food industry. Not just from a production standpoint, but also as part of a broader vision focused on automation, sustainability, and digitalisation.

Kornelis Caps & Closures, celebrating its 90th anniversary next year, has grown into a leading player in plastic closures. Founded in 1936, the company originally started with bakelite products, such as armrests. Over the decades, the focus gradually shifted to the development and production of caps and closures for the food industry – a specialisation that has paid off.

“Every week, millions of caps are shipped out,” says Peter Gols, Senior R&D.

24/7 production

The production facility in Steenwijk runs continuously – 24 hours a day, seven days a week. The team consists of around 75 to 80 permanent employees, supported by a flexible workforce. The core of the machine park includes 32 injection moulding machines, supplemented by post-processing machines for inserting tamper-evidence seals. Kornelis also operates an In-Mould Labelling machine.

Given the current labour market shortages, investment in automation is more important than ever. Robots are increasingly taking over physically demanding tasks, such as stacking boxes.

“We want our operators to focus on process monitoring and quality control – not on moving boxes,” says Gols. “As a company, we aim to offer our people a healthy and sustainable work environment.”

Investing in the machinepark

Thiele & Kor Plastics Machinery recently delivered three fully electric Sumitomo-Demag injection moulding machines: two IntElect S 130-ton models and one IntElect S 180-ton model. The machines were customised to Kornelis’s requirements for fast cycle times and ultra-low energy consumption. They are also equipped with robotics to further support automation. A thorough decision-making process preceded the investment. “We visited multiple companies to see how the machines perform in real-world production, and to evaluate service and reliability,” explains Technical Manager Fabian Ruiter. “In the end, you're not just choosing the best machine – you're choosing a reliable long-term partner. And we found that partner in Thiele & Kor.” “In the pre-installation phase, we visited the factory in Germany to discuss all technical details so that everyone was aligned on expectations. Even now, months after installation, TKPM is still here with a process specialist from Demag, helping to optimise the machines and guide our setters in using the full potential of these highly dynamic systems.” The machines were installed quickly and fully operational within weeks. Minor issues were resolved rapidly. “We send a photo or raise a question, and we get a solution within a day,” says Gols. “Achieving great results together in a positive way – that’s true partnership.”

Less manual, more digital

The new machines are part of a broader shift at Kornelis towards the digitalisation of the injection moulding process. In recent years, Kornelis has made significant investments in measurement and control systems. The company now uses a modern 3D measuring bench, and increasingly checks product properties digitally rather than relying solely on visual or manual inspection. “In the past, setting up a machine largely depended on the experience of the process engineer, who would tweak parameters until the product came out right. Now, we aim for a process where the machine maintains optimal settings within defined tolerances,” explains Gols. “Operators supervise, but only intervene when there’s a real deviation.” This shift requires a cultural change on the production floor. “Some operators needed time to adjust to the idea that they can’t just ‘tweak’ things based on their own instincts anymore,” says Ruiter. “But in the end, they see the benefits: more stability, fewer disruptions, and a calmer, more manageable workflow.”

Certified for quality en safety

Alongside digitalisation, sustainability and regulation are increasingly important. Kornelis mainly produces for the food industry and is certified according to the FSSC 22000 food safety standard, as well as ISCC PLUS for sustainable materials. The company is also proactively adapting to new European regulations like the PPWR (Packaging and Packaging Waste Regulation). “We’re removing as many additives from our materials as possible,” says Gols. “The simpler the composition, the easier the material is to recycle.”

Electric machine, local economy

Electric machine, local economy

The choice for electric injection moulding machines also reflects Kornelis’s sustainability goals. These machines consume significantly less energy than hydraulic models and are more compatible with future digitalisation. Kornelis aims to phase out all hydraulic machines by 2030. “If we replace two machines per year, we’ll hit that target,” Ruiter adds. “You’re probably going to get a lot of phone calls from our competitors now,” jokes Jarno Thiele from TKPM. “But we’re ready for the challenge. Bring it on.” Kornelis also deliberately chooses European suppliers – not just for quality and reliability, but to promote sustainability. “It’s hard to justify shipping machines from the other side of the world when there are excellent alternatives right here in Western Europe,” says Ruiter. “Plus, we want to support the local economy.”

90 years young

Next year, Kornelis celebrates 90 years in business. This milestone is an opportunity to reflect on a rich history – and to look ahead. The ambition is clear: Kornelis aims to lead in the packaging industry, not only in producing high-quality caps and closures, but also in digitalisation, and sustainable, efficient production. With investments in new machinery, increased automation, and a commitment to strong European partnerships, that future is being built step by step.